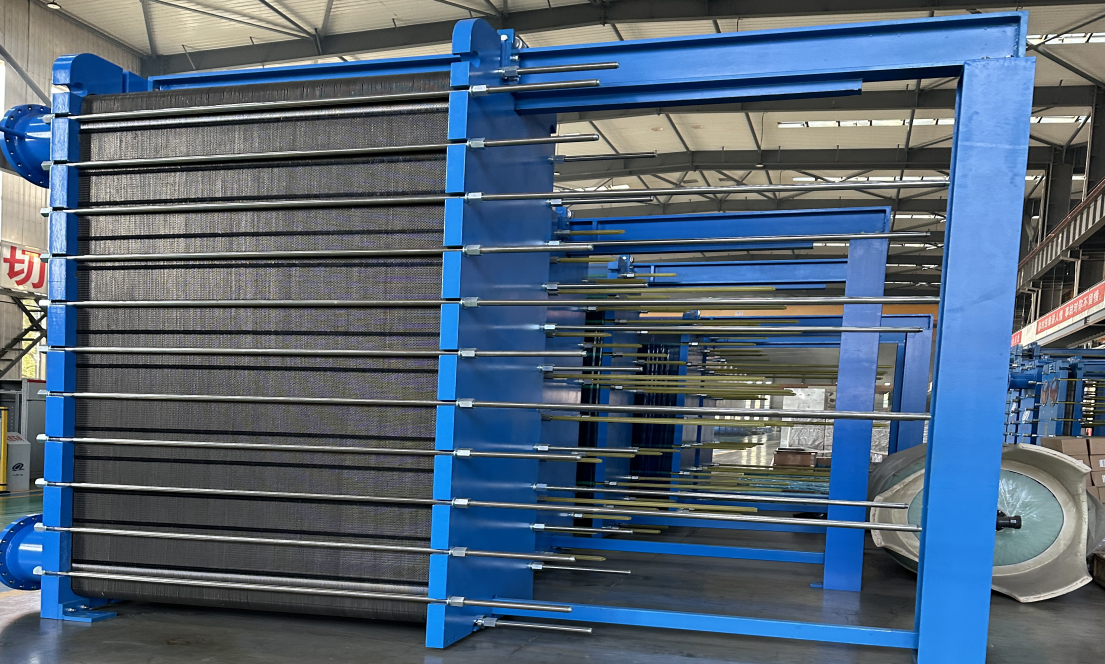

How to prevent corrosion in the daily use of plate heat exchangers?

Release time:

2025-06-17

During the daily use of plate heat exchangers, the following six key technologies can be adopted to achieve effective anti-corrosion:

1.Medium pre-treatment

Implement multi-stage filtration (with a precision of 5μm) and electrochemical desalination for the circulating water, and control the Cl⁻ concentration to be less than 200ppm.

Daily test the pH value (range 6.5-8.5), and automatically add buffer agents (sodium bicarbonate/boric acid) when the fluctuation exceeds ±0.3.

2.Dynamic flow rate control

Maintain the flow rate within the range of 1.0 - 1.8 m/s. When it is lower than 0.8 m/s, activate the turbulence-enhancing pump.

Install a V-shaped deflector plate (at an angle of 30°) at the manifold to eliminate more than 90% of the stagnant flow dead zones.

3.Intelligent drug dosing

Use a three-channel corrosion inhibitor system (molybdate + silicate + organic amine), with the concentration maintained at 20-50 ppm.

Perform polarization curve tests weekly. Adjust the formulation ratio when the corrosion current is greater than 1 μA/cm².

4.Surface condition monitoring

Daily infrared thermal imaging scans (with an accuracy of 0.1℃), areas with a temperature difference greater than 3℃ are marked as corrosion risk points.

Portable electrochemical probes (with a resolution of 1mV) are used to inspect the plate potential. Abnormal points are repaired with coatings.

5.Scientific cleaning management

Monthly implementation of a citric acid (5%) + surfactant (0.2%) circulation cleaning process, with a flow rate controlled at 0.5 m/s.

Replacement of steel wire brushes with micro-particle spraying (glass beads with a particle size of 50 μm) to maintain a surface roughness of Ra ≤ 0.8 μm.

6.Environmental control

During shutdown, nitrogen purging (with dew point <-40℃) is used to maintain system dryness.

In humid environments, the surface of the plates is sprayed with water-replacement type anti-rust oil (thickness 3-5μm).

Key operation points: Record the coefficient of variation of operating parameters (pressure, temperature, flow rate) daily. When the standard deviation exceeds 15% for three consecutive days, initiate a deep inspection. It is recommended to combine with acoustic emission technology (frequency range 50-200kHz) for real-time monitoring of stress corrosion crack propagation.

Related Links:

How to repair plate heat exchangers?

How to manufacture a plate heat exchanger?