How work a plate heat exchanger?

Release time:

2025-01-16

A plate heat exchanger is a device that exchanges heat through multiple thin metal plates. Its core is the process of heat transfer between hot and cold fluids through the plates. The following is a detailed description of its working process:

1. Equipment structure

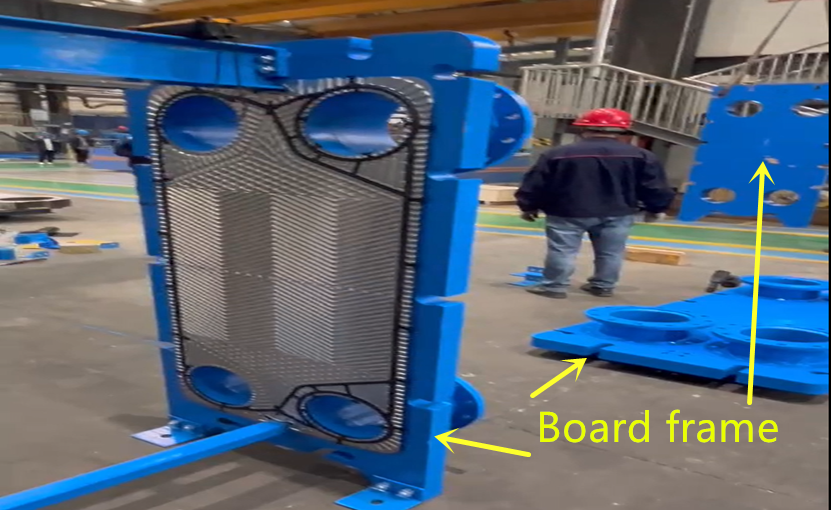

1.1.A plate heat exchanger consists of the following key components:

1.2.Heat transfer plate: a metal sheet mainly used for heat transfer with a corrugated surface.For plate manufacturing of plate heat exchangers, please refer to“How to manufacture a plate heat exchanger?”

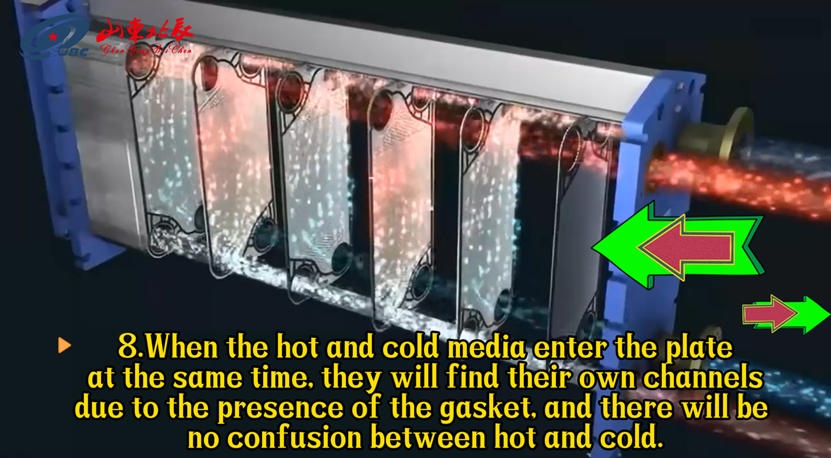

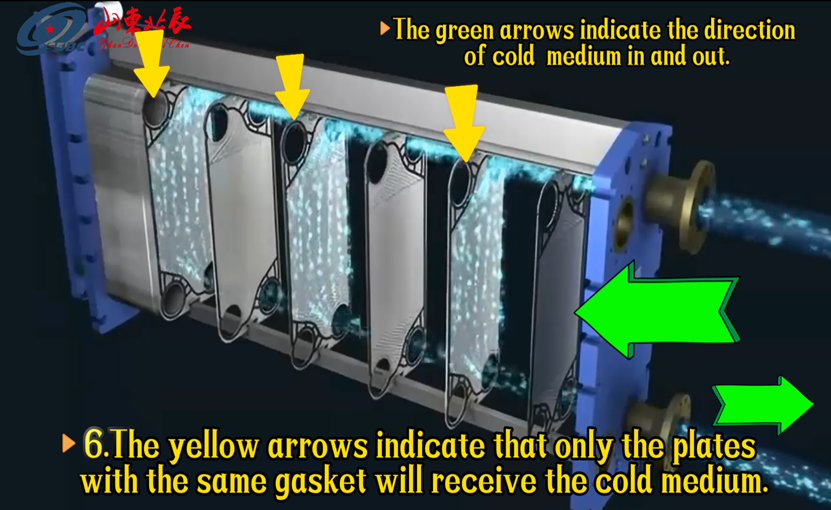

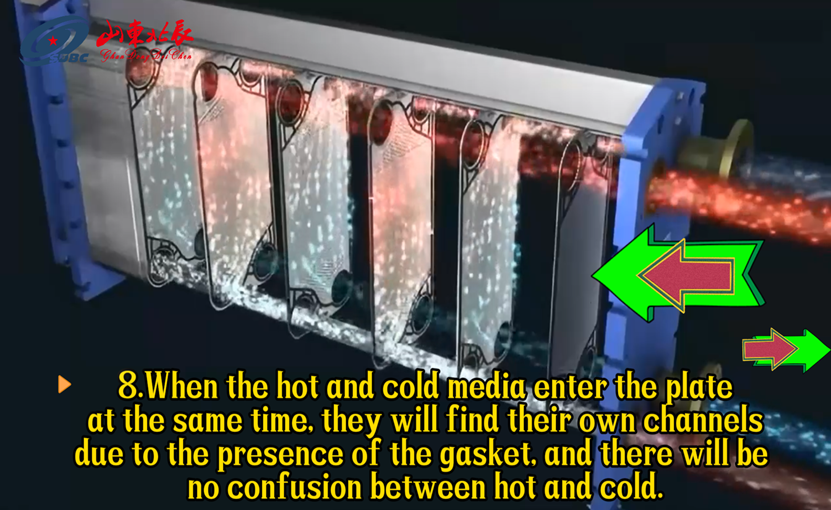

1.3.Sealing gasket: forms a seal between the plates to prevent the mixing of hot and cold fluids.

1.4.Frame system: consists of a fixed pressure plate, a movable pressure plate and clamping bolts, which are used to fix the plates and provide clamping force.

1.5.Fluid inlet and outlet: hot and cold fluids enter and flow out through the inlet and outlet channels of the device respectively.

2. Heat exchange process

The working process of a plate heat exchanger includes the following key steps:

2.1. Introduction of fluid

2.1.1.Hot fluid entry: high-temperature fluid enters the device through the hot fluid inlet of the device.

2.1.2.Cold fluid entry: low-temperature fluid enters from the cold fluid inlet.

The two fluids enter the adjacent plate channels respectively and always remain separated.

2.2. Fluid flow

2.2.1.Alternating flow of hot and cold fluids: The two fluids are separated by plates and sealing gaskets inside the equipment, so that they flow through adjacent channels respectively.

2.2.2.Flow mode:

Countercurrent mode (common): The cold fluid and the hot fluid flow in opposite directions, and the heat exchange efficiency is higher.

Parallel flow mode: The cold fluid and the hot fluid flow in the same direction, and the efficiency is slightly lower.

2.3.Heat transfer

2.3.1.Heat conduction:

The high-temperature fluid transfers heat to the low-temperature fluid on the other side of the plate through the plate. Because the plate is thin and has good thermal conductivity (such as stainless steel or titanium alloy), heat can be transferred quickly.

2.3.2.Turbulence enhances heat transfer:

The corrugated design on the plate makes the fluid form turbulence when flowing, breaking the boundary layer effect and improving the heat transfer coefficient.

2.4.Temperature change

2.4.1.Cooling down of hot fluid:

The hot fluid continuously releases heat when flowing through the channel, and the temperature at the outlet is significantly reduced.

2.4.2.Heating up of cold fluid:

The cold fluid absorbs the heat released by the hot fluid, and the temperature at the outlet is significantly increased.

2.5. Fluid discharge

The hot fluid and the cold fluid are discharged from the outlets respectively, completing the heat exchange process.

3. Optimization of the working process by key designs

3.1.Counterflow design:

Maintain a high average temperature difference between the hot and cold fluids, increase the heat transfer driving force, and thus improve the heat exchange efficiency.

3.2.Corrugated design:

Increase the heat transfer area, enhance the turbulence effect, and at the same time improve the mixing of the fluids to prevent scaling.

3.3.Adjustability:

By increasing or decreasing the number of plates, the heat exchange capacity can be flexibly adjusted to meet the needs of different working conditions.

4. Precautions during work

4.1.Sealing:

Ensure the integrity of the sealing gasket to avoid mixing or leakage of hot and cold fluids.

4.2.Fluid characteristics:

For corrosive, high-viscosity or particle-containing fluids, it is necessary to select appropriate plate materials and corrugated designs.

4.3.Maintenance and cleaning:

Clean the plate surface regularly to prevent dirt and scaling from affecting the heat transfer performance.

5. Performance of heat exchange efficiency

Through the counterflow mode and turbulence enhancement design, the heat exchange efficiency of the plate heat exchanger can usually reach more than 90%. In actual work, it can effectively recover heat energy, reduce energy consumption, and adapt to a variety of industrial and civil needs.

6.summary

The working process of the plate heat exchanger is an efficient, compact and flexible heat transfer process, and excellent performance is achieved through optimized design. If you need specific application cases or further details, feel free to let me know!