Support protection before transportation

Release time:

2025-06-23

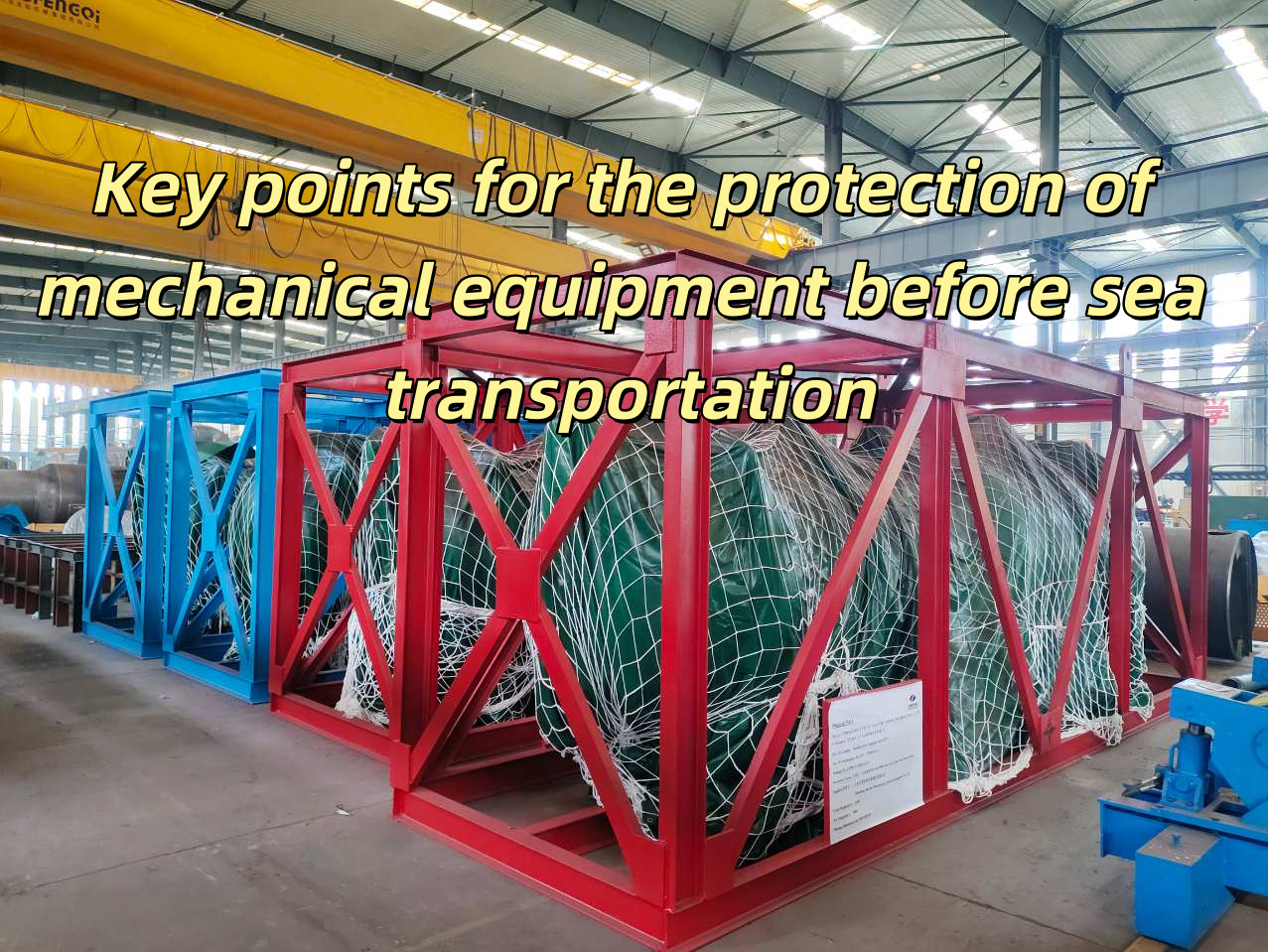

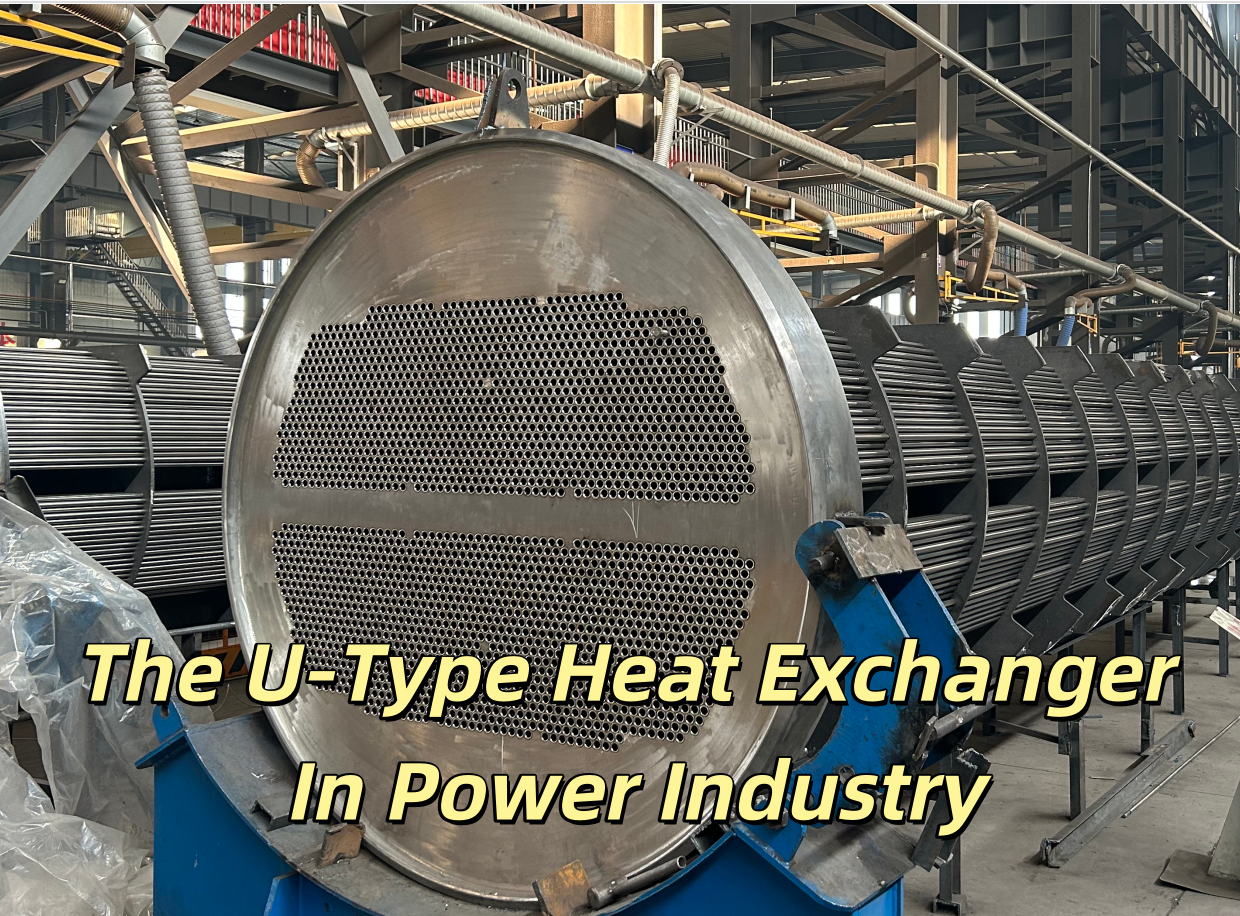

When transporting marine electrical and mechanical equipment, some products require specialized support structures to be installed to prevent structural damage or functional failure during transportation. The support structure protection and preparatory work for many mechanical equipment, such as closed water coolers before maritime transportation need to focus on implementing the following technical measures:

Transportation support technical parameters

1.Material selection

Corrosion-resistant steel or aluminum alloy brackets should be given priority. The crossbeam should meet the load-bearing standard of more than 1.5 times the weight of the equipment

The contact surface is equipped with rubber gaskets of 3mm or more to prevent direct friction between metals.

2.Structural design

The triangular support structure is designed according to the distribution of the equipment's center of gravity, with a focus on protecting the precision components.

The welding nodes need to be ensured to have no false welding.

The gap between the equipment and the bracket is controlled at 10-15mm.

3.Equipment fixation method

The equipment should be placed at the center of the support and firmly locked by bolts, steel belts or other reliable fixtures.

Install anti-slip pads (such as rubber pads or wooden boards) between the bottom of the equipment and the contact surface of the support to reduce frictional damage and improve stability.

For large equipment, auxiliary support strips should be installed on the top and sides to prevent the equipment from toppling over or moving.

The design and installation of brackets for mechanical and electrical equipment products directly affect the safety and integrity of equipment transportation. Therefore, the installation of the support frame before sea shipping is very important