The characteristics and recommendations of titanium tube shell heat exchangers

Release time:

2025-06-19

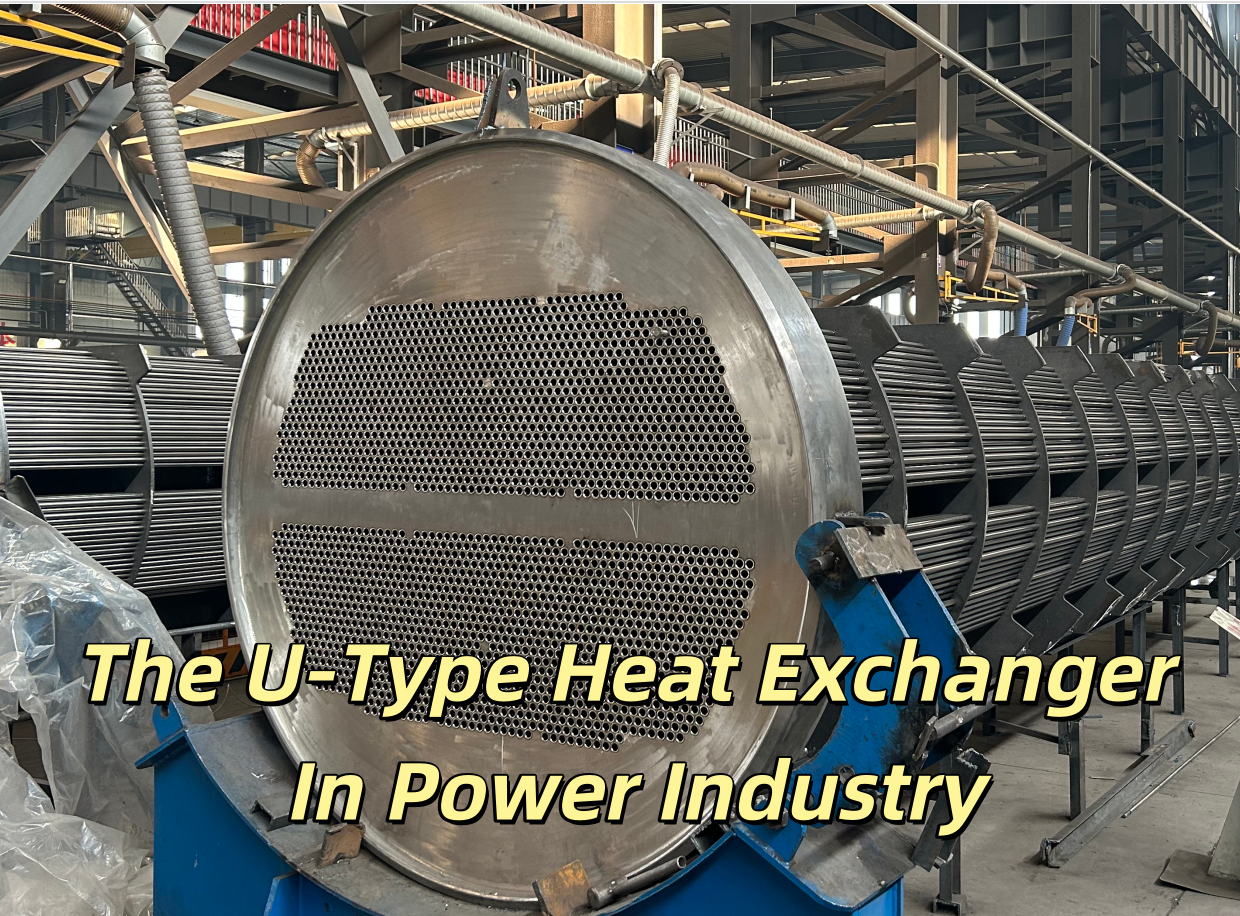

The titanium tube shell heat exchanger is a shell-and-tube type heat exchanger made with titanium as the core material. It is specifically designed for applications involving strong corrosiveness, high cleanliness requirements, or special temperature conditions.

Core structure

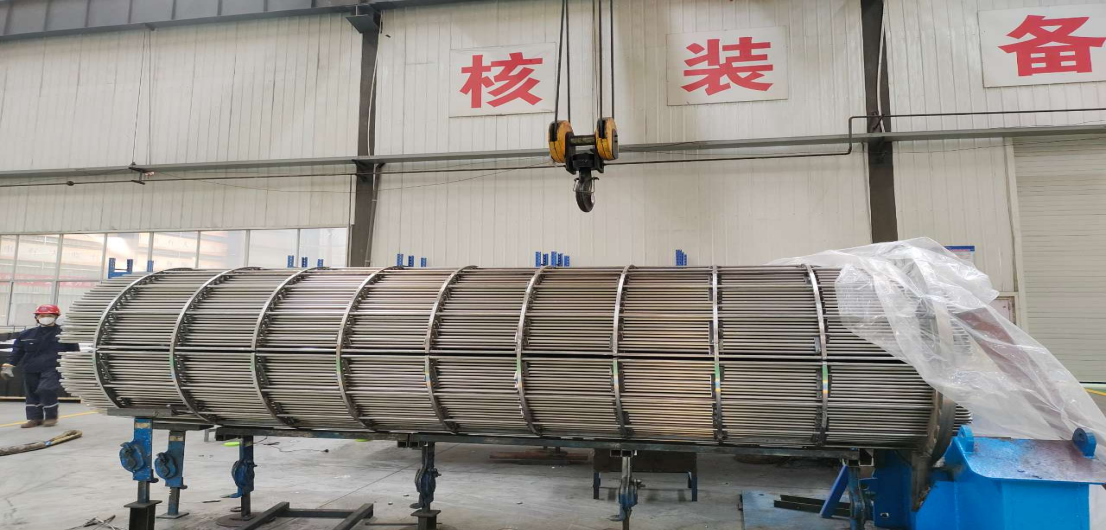

1.Titanium tube bundle

The heat exchange tubes are made of seamless titanium tubes, which are resistant to corrosion by seawater, chloride ions, and acidic and alkaline media.

Diameter range: Φ10 - 50mm, wall thickness 0.5 - 3mm. Customized U-shaped/straight tube arrangement is available.

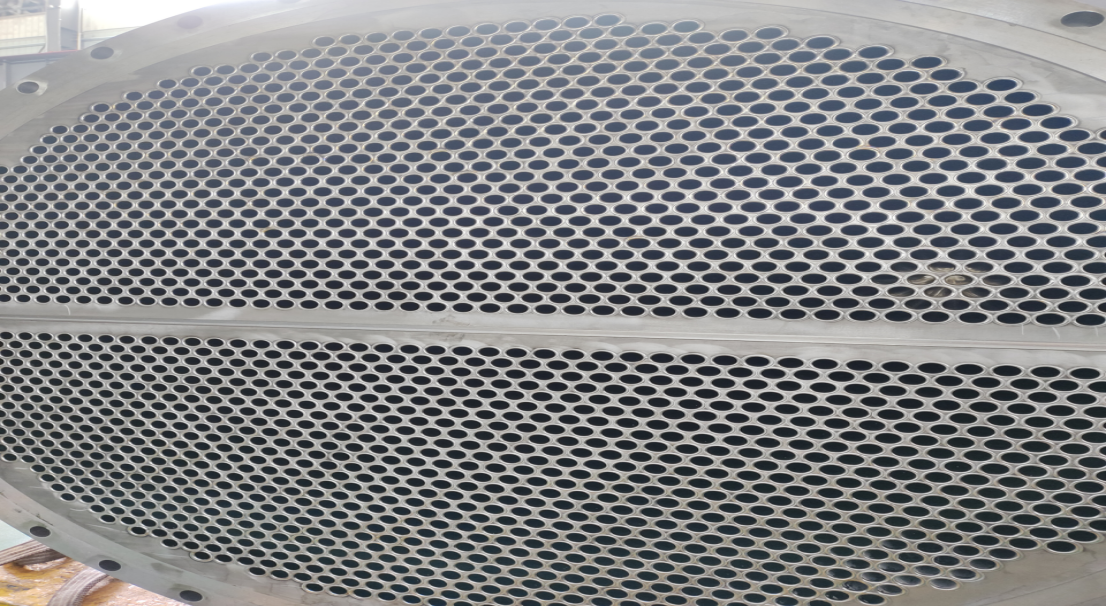

2.Tube sheet and shell

Titanium tube sheet: Fixed to the titanium tubes through both strength expansion connection and sealing welding, preventing crevice corrosion.

Shell: Available options include all-titanium (high cost but corrosion-resistant), titanium-steel composite plate (cost-effective solution), or carbon steel inner lining with titanium (for low-pressure applications).

Core advantages:

Corrosion resistance: Lifespan is over 10 times that of stainless steel in media containing Cl⁻, H₂S, and acidic substances.

High thermal conductivity: The thermal conductivity of titanium (21.9 W/m·K) meets the requirements for efficient heat exchange.

Lightweight: Density is only 60% of that of steel, facilitating installation and transportation.

Hygiene: The TiO₂ oxide film on the surface inhibits microbial attachment, meeting pharmaceutical and food-grade standards.

Typical application scenarios:

Marine engineering: seawater cooling systems, heat recovery devices for offshore platforms.

Chemical industry: hydrochloric acid coolers, preheaters for wet chlorine gas (chlor-alkali industry).

Nuclear power: nuclear-grade auxiliary heat exchange equipment (resistant to borate corrosion).

New energy: high-temperature chloride heat exchange in lithium battery material production.

Selection suggestions:

Media matching: It is recommended to be used in media environments where the concentration of Cl⁻ is greater than 200 ppm or the pH value is less than 4 or 10.

Economy: The all-titanium solution is suitable for high-pressure/long-term operation scenarios. For low-pressure situations, a titanium-lined structure can be chosen.

Maintenance: Regularly inspect the welds of the tube plate and the expansion joint area to prevent micro-leaks that may cause corrosion of the shell.

Related Link:

Preparations before installing tubes in the titanium plate heat exchanger