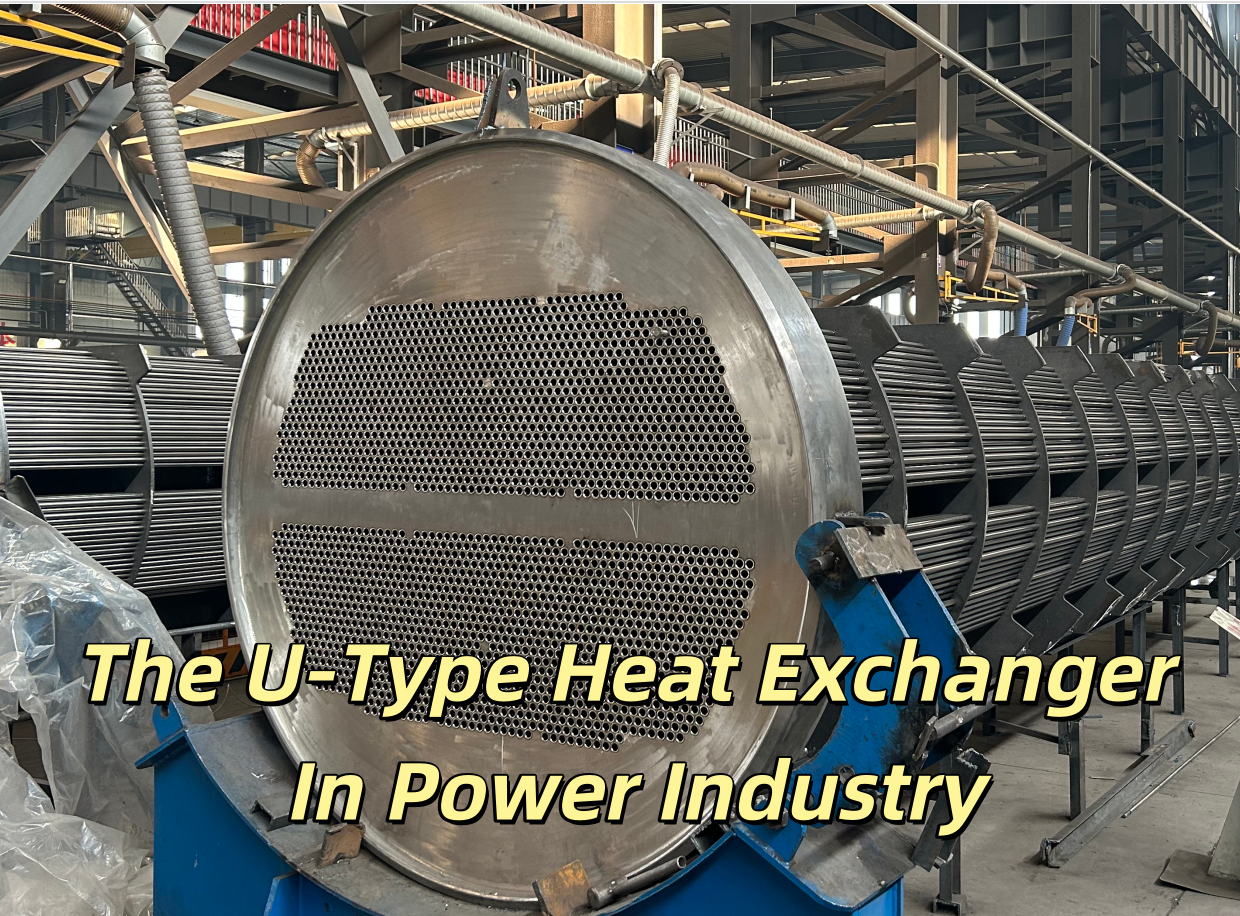

Tube threading for the heating network heater

Release time:

2025-05-26

The "pipe penetration" of the heating network heater usually involves the installation or maintenance of the tubes within the heat exchanger. The key points are as follows:

I. Structural Design

Tube sheet and tube bundle: The drilling accuracy of the tube sheet needs to reach ±0.1mm, ensuring that the tubes (commonly φ19/φ25mm) can be precisely inserted. The expansion rate should be controlled at 5%-8% to avoid leakage.

Sealing process: Dual fixation using hydraulic expansion and sealing welding is adopted. The length of the tube opening extending from the tube sheet is generally 2-3mm, and the welding bevel angle is 35° ± 5°.

Flow baffle spacing: Set according to the TEMA standard, usually 0.8-1.2 times the pipe diameter, to ensure the turbulence effect of the medium.

II. Installation Process

Tube insertion preparation: Use a laser alignment instrument to calibrate the tube sheet holes, and the cleanliness should reach Sa2.5 level (ISO8501).

Tube insertion operation: Apply food-grade lubricating grease (such as Molykote 111) when inserting each tube. The insertion speed should be controlled at 0.5m/min.

Expansion parameters: The hydraulic expansion pressure is usually 35-50MPa (for carbon steel). The expansion length should be the tube plate thickness + 3mm.

III. Special Conditions Handling

Thermal compensation design: Set Ω-shaped expansion joints, with the compensation amount calculated as ΔL = α·L·ΔT (α takes 12.5×10⁻⁶/℃).

Anti-vibration measures: When the cross-flow velocity is greater than 3m/s, anti-vibration strips should be set, with the spacing not exceeding 10 times the pipe diameter.

Corrosion prevention treatment: In seawater conditions, the tube bundle should use duplex steel (such as 2205) or titanium material, and the tube plate should be welded with 2mm thick 625 alloy.

IV. Maintenance Key Points

Leak detection standard: The gas tightness test pressure is 1.15 times the design pressure, with a holding time of ≥30min and a pressure drop of <1%.

Chemical cleaning: Acid washing is required every 8000 hours (5% citric acid + 0.2% inhibitor) at a flow rate of 1m/s.

Tube bundle replacement: When the wall thickness reduction is greater than 20% or the blocked tube rate is greater than 10%, the entire tube bundle needs to be replaced.

It is recommended to use tube hole guide devices (with positioning accuracy of ±0.05mm) and use eddy current testing (ECT) to ensure the straightness deviation of the tubes is <1/1000. For large heating devices with a diameter of DN800 or above, it is recommended to use split tube insertion, and set temporary support frames to prevent the tube bundle from deforming.

Related Links:

Maintenance of high and low pressure heaters