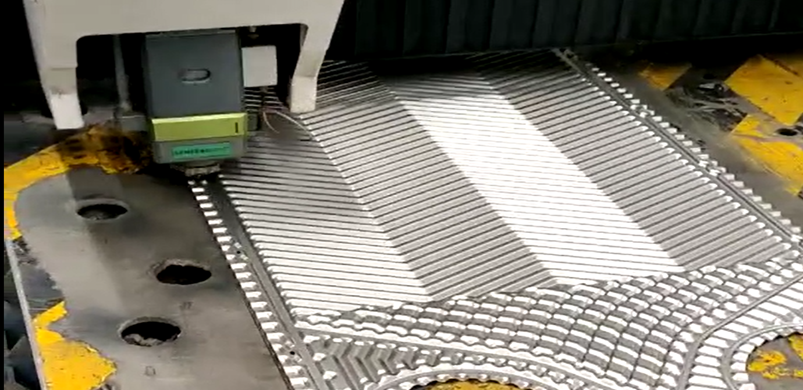

Hidden hanging hooks and laser cutting of plate heat exchanger plates

Release time:

2025-05-12

The combination of the hidden hanging buckle design of the plate heat exchanger and the laser cutting process is a key technical point for enhancing product performance and manufacturing efficiency. The following is an analysis from three aspects: design, process and advantages:

1.Key points of hidden buckle design

Structural optimization: Hidden hooks typically adopt embedded slots or folded edge structures to prevent protruding components from interfering with fluid distribution. The stress distribution in the buckle area under compression (above 2.5MPa) needs to be verified through finite element analysis (FEA) to ensure that the strength meets the standard.

Sealing performance: A precise gap of 0.1-0.3mm should be designed at the junction of the hook and the plate, and a double seal can be achieved by using EPDM/NBR gaskets. The leakage rate can be controlled below 0.01%.

Assembly efficiency: By adopting a 45° inclined insertion guide structure, the time for plate assembly is reduced by 30%, and a single person or shift can complete the assembly of 80 to 100 plates.

2.Laser cutting process parameters

Equipment selection: It is recommended to use the IPG 6kW fiber laser. When cutting 304 stainless steel, the speed can reach 12m/min (1.5mm thick), the taper of the cut is less than 0.02°, and the roughness Ra is ≤6.3μm.

Precision control: A CCD vision positioning system is adopted, with a repeat positioning accuracy of ±0.01mm, ensuring that the tolerance of the buckle slot is controlled within H7 grade (+0.018/-0mm).

Heat-affected zone control: Nitrogen-assisted cutting can reduce the heat-affected zone (HAZ) to below 50μm, with a microhardness fluctuation of less than 10HV, avoiding the risk of intergranular corrosion in the hanging area.

3.Technical and economic advantages

Material utilization rate: The nested layout algorithm enables the sheet material utilization rate to reach 92%, which is 15% higher than that of the traditional stamping process. Each unit saves approximately 3.2 tons of stainless steel coil material per year.

Mold cost: Laser cutting does not require the development of stamping molds, shortening the new product development cycle by 60% and reducing the trial production cost by 80%.

Maintenance convenience: The hidden structure increases the plate cleaning pass rate by 40%, and the chemical cleaning cycle can be extended to over 6,000 hours.

It is recommended to conduct 3000 pressure pulse tests (0-2.5MPa, 1Hz) before mass production, and use blue light scanning to detect the assembly gap of the hangers to ensure batch consistency. This solution has been successfully applied in the liquid cooling system of the data center with a single-module heat exchange capacity of 500kW.

Related Links:

How to install the rubber rings between the plates?

Welded plate heat exchanger plates

The machining and drilling of the heat exchanger tube sheet