How to install the rubber rings between the plates?

Release time:

2025-04-29

Installing the rubber rings between the plates of the plate heat exchanger requires meticulous operations. The following are the specific steps and precautions:

Installation Steps

1.Preparation Work

-

- Clean the Plates: Thoroughly clean the plate groove positions with a soft cloth and non-corrosive cleaner to ensure no residual dirt or old rubber ring fragments.

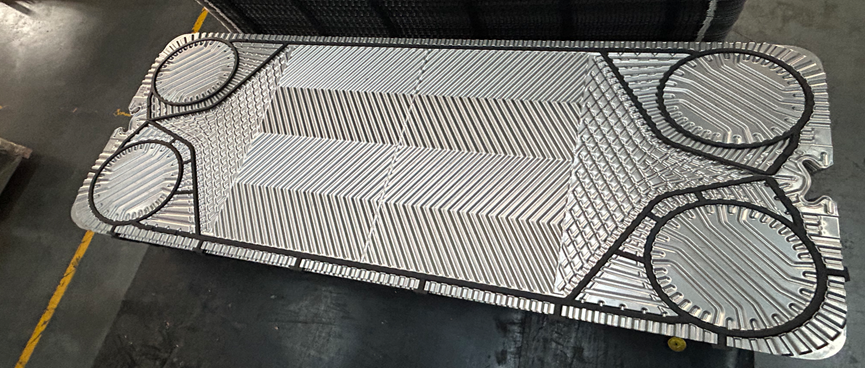

- Inspect the Rubber Rings: Confirm that the new rubber rings are free of damage, deformation, and that the size matches the plate groove positions. If it is a directional rubber ring, pay attention to distinguishing the front and back sides.

2.Install the Rubber Rings

-

- Lubricate the Groove Positions: Evenly apply a small amount of silicon-based lubricant (avoid petroleum-based grease that may corrode the rubber) to the plate groove positions to reduce the installation resistance.

- Embed the Rubber Rings: Start from one end and use fingers or a plastic crowbar to gradually press the rubber rings into the grooves, ensuring a complete fit without twisting or stretching.

- Lubricate the Groove Positions: Evenly apply a small amount of silicon-based lubricant (avoid petroleum-based grease that may corrode the rubber) to the plate groove positions to reduce the installation resistance.

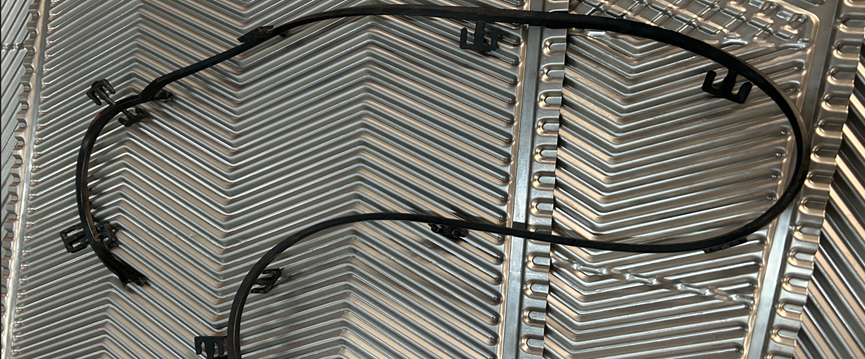

3.Alignment and Fixation

-

- Check the Sealing Surface: After installation, gently press the rubber rings to confirm that they are flush with the edge of the plate without local bulges or depressions.

- Fix the Clips (if any): If the rubber rings have clips or positioning pins, they need to be aligned with the plate holes and fastened to prevent displacement.

4.Assemble the Plate Group

-

- Stack in Order: Assemble according to the original plate sequence and flow direction marks, with the sealing surface of the rubber rings facing the correct direction (usually towards the adjacent plates).

- Uniformly Compress: Use the compression screw or hydraulic tools to gradually and symmetrically apply pressure to ensure that the plate group is evenly stressed to avoid rubber ring deformation due to excessive pressure on one side.

5.Pressure Test

-

- Hydrostatic Test: Fill with clean water, slowly increase the pressure to 1.5 times the design pressure, and hold the pressure for 30 minutes to check for leaks. If there is a leak, it is necessary to disassemble and re-adjust the rubber rings.

Precautions

- Avoid Violent Operations: Forcibly pulling or using metal tools may scratch the rubber rings or plates.

- Ambient Temperature: The installation environment should be between 5 - 35°C to avoid the rubber becoming hard due to low temperature or sticky due to high temperature.

- Replacement of Old Rubber Rings: If it is a maintenance replacement, it is necessary to simultaneously check whether the adjacent plates are corroded or deformed to avoid repeated leaks.

Related Links: