How to select plate heat exchangers (PHE) ?

Release time:

2025-06-11

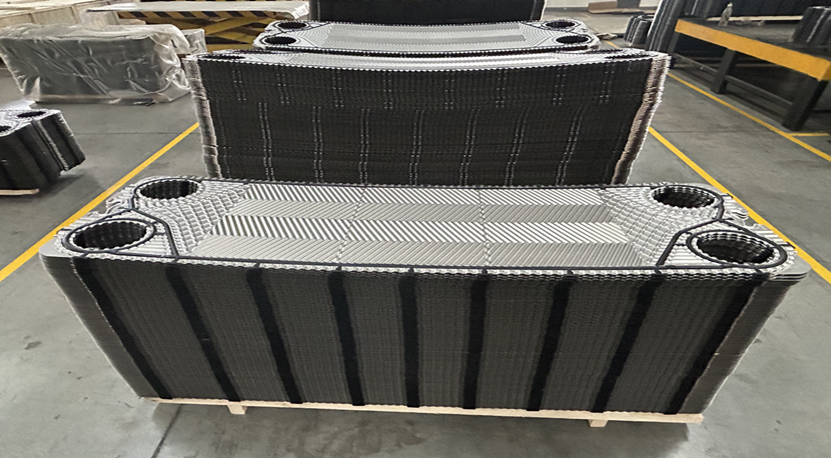

The selection of detachable Plate Heat exchangers (PHE) requires comprehensive consideration of factors such as process parameters, medium characteristics, space limitations and economy. The following are the detailed selection steps and key points:

1. Clarify the process parameters

1.1. Flow rate: Determine the volume or mass flow rate of the hot and cold fluids (m³/h or kg/h).

1.2. Temperature: Inlet/outlet temperature (℃), calculate the logarithmic mean temperature difference (LMTD).

1.3. Pressure drop limit: The maximum allowable pressure drop (typically ≤0.1MPa), which affects the plate design and flow rate selection.

1.4. Heat load, heat transfer (kW or kcal/h), through the equation Q=m⋅cp⋅ΔT calculation.

2. Analysis of medium characteristics

2.1. Physical properties: Density, specific heat capacity, thermal conductivity, viscosity.

2.2. Chemical Properties:

2.2.1. Corrosiveness (such as chloride ions, acidic media) : Select corrosion-resistant materials such as titanium and Hastelloy.

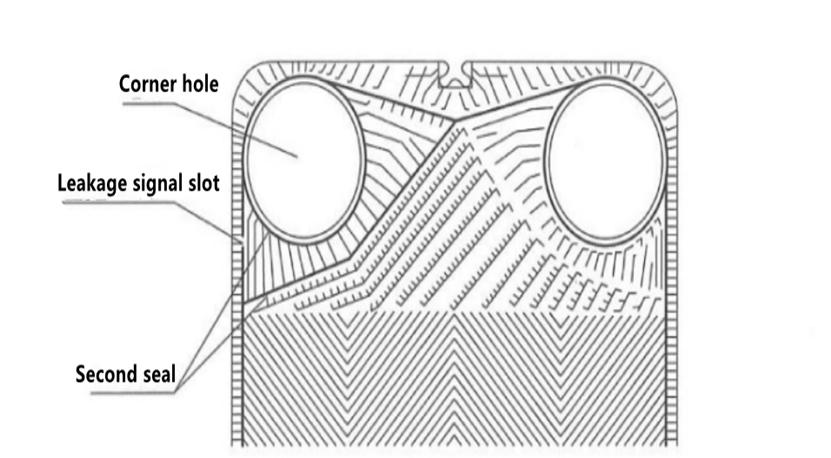

2.2.2. Tendency to Scale: For high-fouling fluids, wide channel plate types or detachable cleaning designs should be selected.

2.2.3. Particulate Matter content: For media containing particles, single-sided flow or asymmetric flow channels should be selected.

3. Plate design selection

3.1. Plate material:

3.1.1. Stainless Steel (304/316) : Conventional medium.

3.1.2. Titanium/titanium-palladium alloy: Seawater, corrosive media.

3.1.3. Graphite/Plastic: Strong acid and strong alkali.

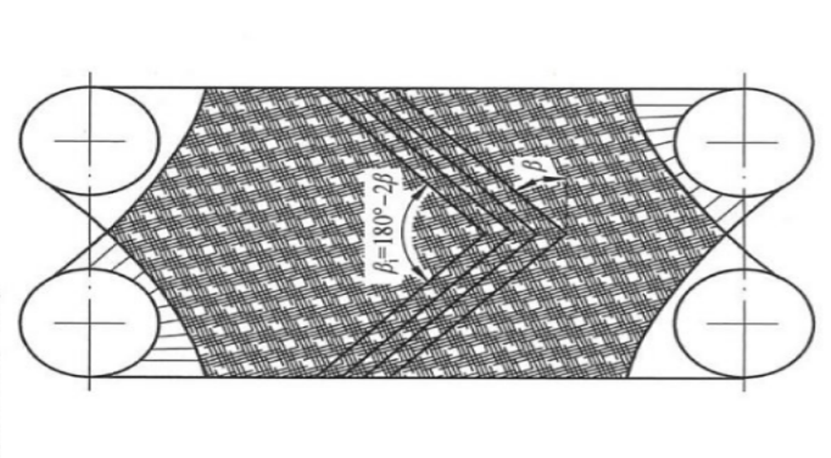

3.2. Plate Type Design:

3.2.1. Ripple Angle (such as 60° high heat transfer /30° low pressure drop).

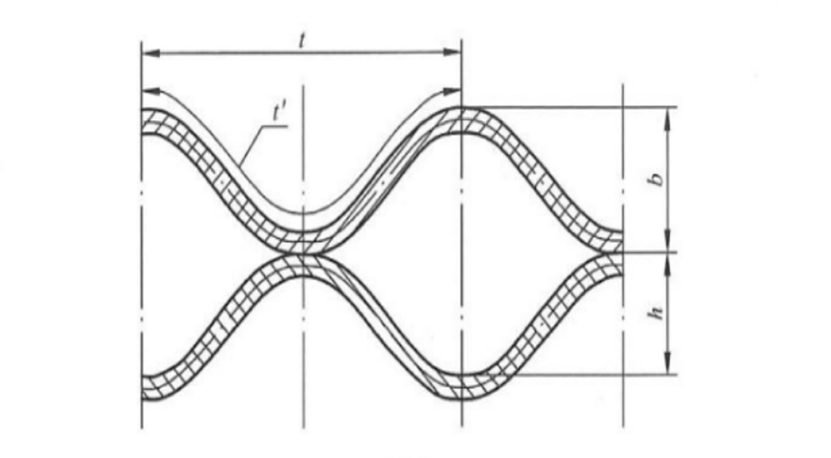

3.2.2. Plate thickness (0.4-1.0mm) : Affects pressure resistance and corrosion resistance.

3.3. Gasket: Select NBR, EPDM, fluororubber, etc. according to the temperature/medium.

4. Calculate the heat exchange area

4.1. Heat transfer coefficient (U value) : It is usually 3000 to 7000 W/(m²·K), and it needs to be estimated in combination with the medium and flow rate.

4.2. Correct LMTD: Consider the flow mode (counter-current/co-current) and the efficiency correction factor.

4.3. Safety margin: Increase the area by 10% to 20% to deal with dirt or fluctuations in working conditions.

5. Determine the structural parameters

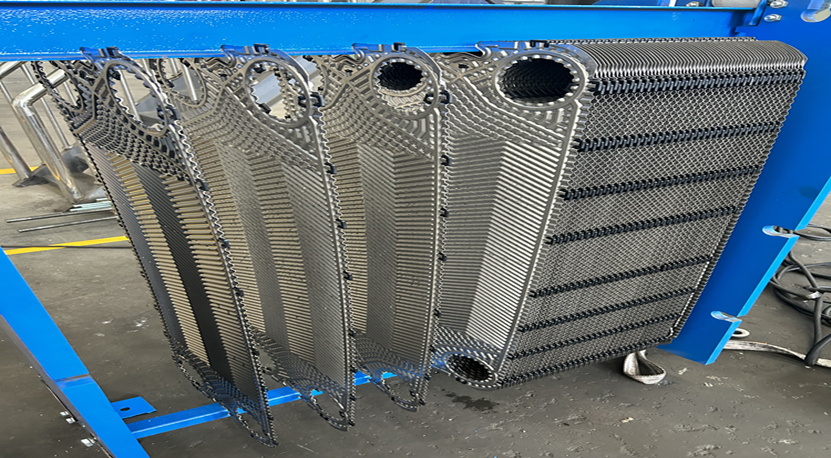

5.1. Number of boards: Calculated based on the area of each board and the total required area.

5.2. Flow channel Layout:

5.2.1. Single Process/Multiple Processes: Pressure Drop and Temperature Difference Trade-off.

5.2.2. Symmetrical/Asymmetrical flow channels: Suitable for working conditions with significant flow rate differences.

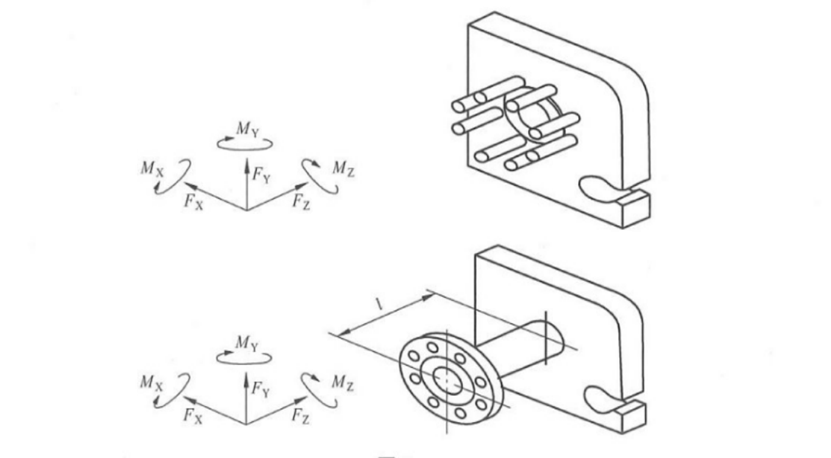

5.3. Interface size: Match the pipe diameter to avoid excessive local resistance.

6. Verify the pressure drop and flow rate

6.1. Flow velocity range: 0.2-1.0 m/s for liquids, 10-30 m/s for gases.

6.2. The pressure drop formula: ΔP=f⋅(L/dh)⋅(ρv2)/2, need to meet the technological requirements.

7. Special working condition handling

7.1. High temperature/High Pressure: Select brazed type or semi-welded type (pressure resistance ≤2.5MPa, temperature ≤200℃).

7.2. Scale-prone media: Designed for quick disassembly or online cleaning (CIP).

7.3. Vibration environment: Enhance the rigidity of the frame or select a fully welded type.

8. Brand and Cost optimization

8.1. Supplier Comparison: Such as Alfa Laval, APV, GEA, domestic brands, etc.

8.2. Cost Trade-off: Initial investment vs. Maintenance costs (such as the frequency of gasket replacement).

9. Software selection and verification

9.1. Simulate using the manufacturer's selection software (such as HTRI, SWEP), or provide parameters and entrust the manufacturer to design.

9.2. Conduct small-scale trials or on-site tests when necessary.

10. Sample selection table

|

Parameters |

Hot side (steam) |

Cold Side (water) |

|

Flow rate (m³/h) |

5 |

10 |

|

Temperature (℃) Inlet/outlet |

120/80 |

20/60 |

|

Allowable pressure drop (kPa) |

≤50 |

≤30 |

|

Material |

316 stainless steel |

NBR gasket |

|

Plate type |

high θ corrugation |

single pass |

Related Links:

How to manufacture a plate heat exchanger?

Top 5 Plate Heat Exchanger Manufacturers in China