The types of marine condensers

Release time:

2025-06-09

The types of marine condensers can be classified from three dimensions: structural form, cooling medium, and installation method. The following are the specific descriptions:

I. Classification by Structural Form

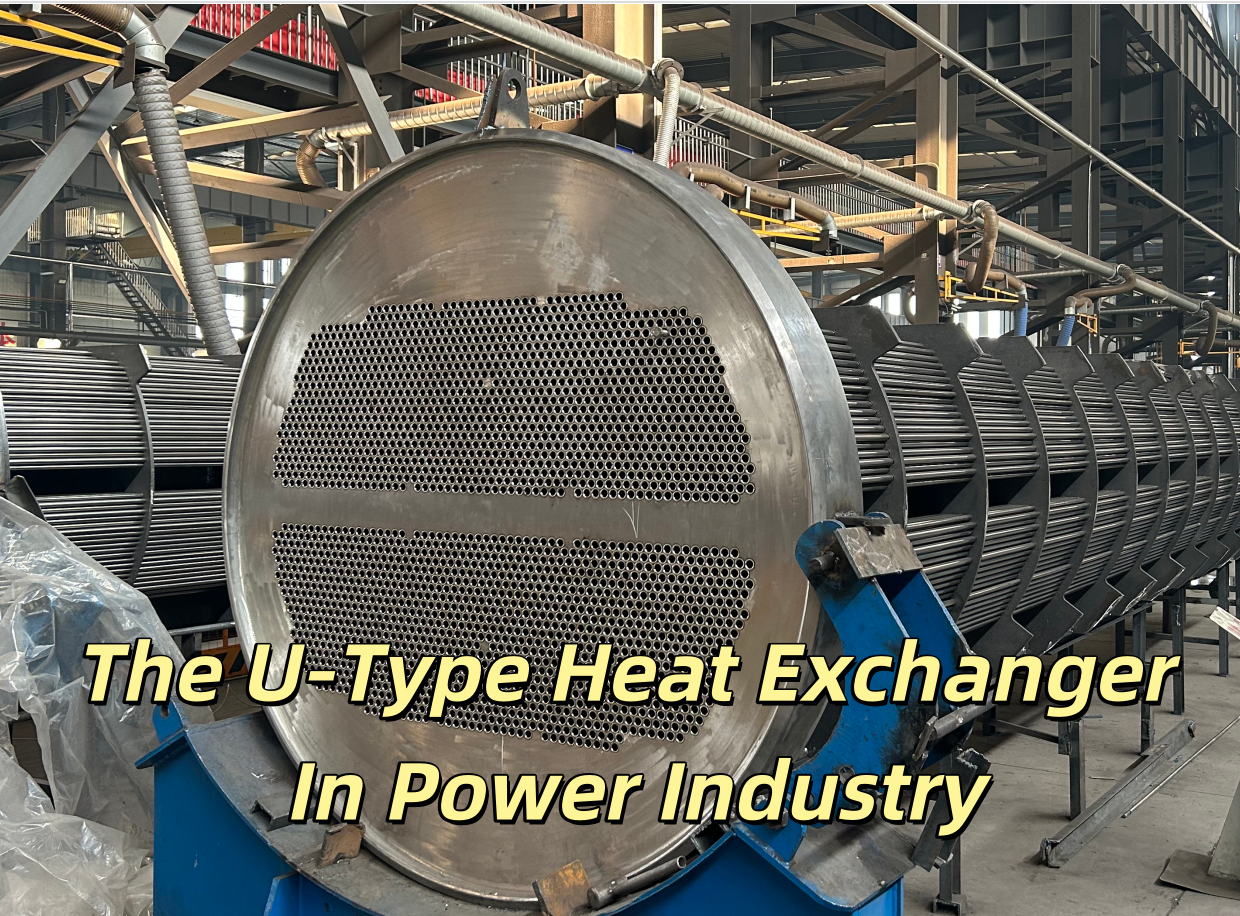

Shell-and-tube Condenser

- Characteristics: A cylindrical shell encloses copper or titanium alloy tubes. Seawater flows through the tube side, and the refrigerant flows through the shell side.

- Application scenarios: Cooling of main propulsion systems and large refrigerated ships.

- Advantages: High pressure resistance (>3.5 MPa) and a long maintenance cycle (>8000 hours).

Plate Condenser

- Characteristics: Corrugated plates are stacked and welded, and the refrigerant and cooling water exchange heat in a counter - flow manner.

- Application scenarios: Air - conditioning systems in passenger cabins and refrigeration systems of lifeboats.

- Advantages: 40% smaller in volume than shell - and - tube condensers and 2 - 3 times higher in heat transfer coefficient.

Double - pipe Condenser

- Characteristics: It has a concentric double - pipe structure. Seawater flows in the outer pipe, and the refrigerant flows in the inner pipe.

- Application scenarios: Refrigeration units of small fishing boats.

- Advantages: Strong vibration resistance, suitable for high - salinity waters.

II. Classification by Cooling Medium

Water - cooled

- Seawater cooling: It is necessary to configure filters and anti - biological pollution devices.

- Freshwater cooling: It is a closed - loop circulation system and requires an additional plate heat exchanger.

Air - cooled

- Characteristics: Heat is dissipated through forced convection by a fan.

- Applicable scenarios: Cooling of deck equipment on offshore engineering ships.

- Limitations: The refrigeration efficiency decreases by about 25% in tropical waters.

III. Classification by Installation Method

Vertical Condenser

- It is installed vertically, which saves deck space, but requires strengthened bottom support.

Horizontal Condenser

- It is installed horizontally, which facilitates pipeline connection and requires regular venting of accumulated gas.

Special Types

- Combined Condensing Evaporator: It integrates the functions of refrigerant condensation and fresh water production and is used on ocean - going ships.

- High - pressure - resistant Deep - diving Type: It is made of titanium alloy and can work at a pressure of up to 10 MPa, used on scientific research ships.

Selection suggestions:

- For ocean - going ships, shell - and - tube condensers are preferred (strong corrosion resistance).

- For small coastal ships, plate condensers can be considered (easy maintenance).

- In areas with a shortage of fresh water, evaporative condensers are recommended (saving more than 90% of water).