How to understand finned tube heat exchangers?

Release time:

2025-05-08

Finned tube heat exchanger is one of the earliest and most successful discoveries in the process of improving tubular heat exchange. This method is still the most widely used method of enhancing heat transfer of all kinds of tubular heat exchange surfaces. It is not only suitable for single-finned tube heat exchangers, but also widely used in power, chemical, petrochemical, air conditioning engineering and refrigeration engineering.

1. Types of finned tubes

1.1. The basic heat transfer element of finned tube heat exchanger is finned tube, which is composed of finned tube base tube and fin. The base tube is usually a round tube, but there are also elliptical tubes and flat tubes.

1.2. The surface structure of the fin includes flat fins, intermittent fins, corrugated fins and perforated fins. Among them, the latter two are high-efficiency heat exchanger types.

2. Structure of finned tubes

2.1. Classification by structural type

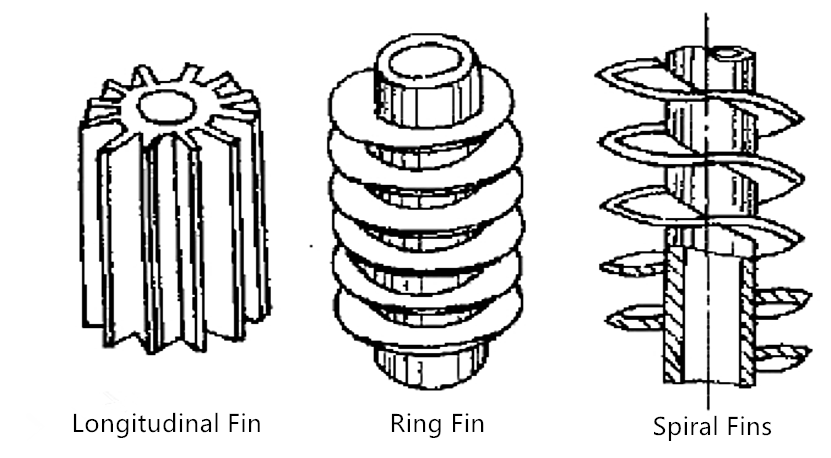

From the structural type, finned tubes can be divided into two basic types: longitudinal and radial. Other types are the development and deformation of these two types. For example, large helical angle finned tubes are close to longitudinal, and small helical angle finned tubes are close to radial. The shapes of fins are round, rectangular and needle-shaped. In addition, the fins can be set outside the tube, called external finned tubes; they can also be set inside the tube, called internal finned tubes or both inside and outside.

2.2. Classification by manufacturing process

According to the manufacturing process, finned tubes can be classified into integral finned tubes, welded finned tubes, high-frequency welded finned tubes and mechanically connected finned tubes.

2.2.1. Integral finned tubes: made by casting, machining or rolling, the fins and tubes are a whole.

2.2.2. Welded finned tubes: manufactured using processes such as brazing or inert gas shielded welding. Modern welding technology can connect fins of different materials together, and can make fin tubes simple and economical, with good heat transfer and mechanical properties, and has been widely used. Since the residue in the weld is not conducive to heat transfer and may even cause fracture, the welding process quality must be guaranteed when producing this type of fin tube.

2.2.3. High-frequency welding fin tube: The high-frequency induction generated by the high-frequency generator generates high temperature at the contact point between the tube surface and the fin, and the two are melted within a depth range of about 10μm, and then pressurized to connect the fin and the tube as one. There is no flux or solder, it is simple to manufacture, has high productivity, and has excellent heat transfer and mechanical properties. This is the most ideal type of fin tube, which is being recognized and adopted by the majority of users.

2.2.4. Mechanically connected fin tubes: There are usually three types: winding type, inlaid type, sleeve type or string type. Finned tubes are easy to manufacture. A metal strip is fixed to one end of the tube by mechanical or welding. The metal strip is tightly wrapped around the outer wall of the tube by the rotational torque of the tube. The other end is fixed to form a finned tube. The material of the strip can be copper strip, steel strip or aluminum strip.

3. Heat transfer calculation

The basic equations for heat transfer calculation of finned tube heat exchangers are the same as those of other tube heat exchangers.

4. Application areas

Finned tube heat exchangers are widely used in power, chemical, petrochemical, air conditioning engineering and refrigeration engineering, such as surface air coolers, air heaters and fan coils used in air conditioning engineering. The evaporator of the air cooler and the evaporator of the frost-free refrigerator used in refrigeration engineering are not only suitable for the flow of single-phase fluids, but also have great value for phase change heat transfer.

Most finned tube heat exchangers used for clean gas adopt a new and efficient fin surface structure, which has achieved significant enhanced heat transfer effect.

Shandong Beichen Mechanical and Electrical Equipment Co., Ltd. has been mainly engaged in fin-tube heat exchangers for many years. It is relatively mature in R&D and technology, and can tailor different types of fin-tube heat exchangers for customers in multiple industries.

Related Links:

Fin Tube Heat Exchanger Manufacturing Process