Hualong One nuclear island heat exchanger

Release time:

2025-04-30

Delivery site

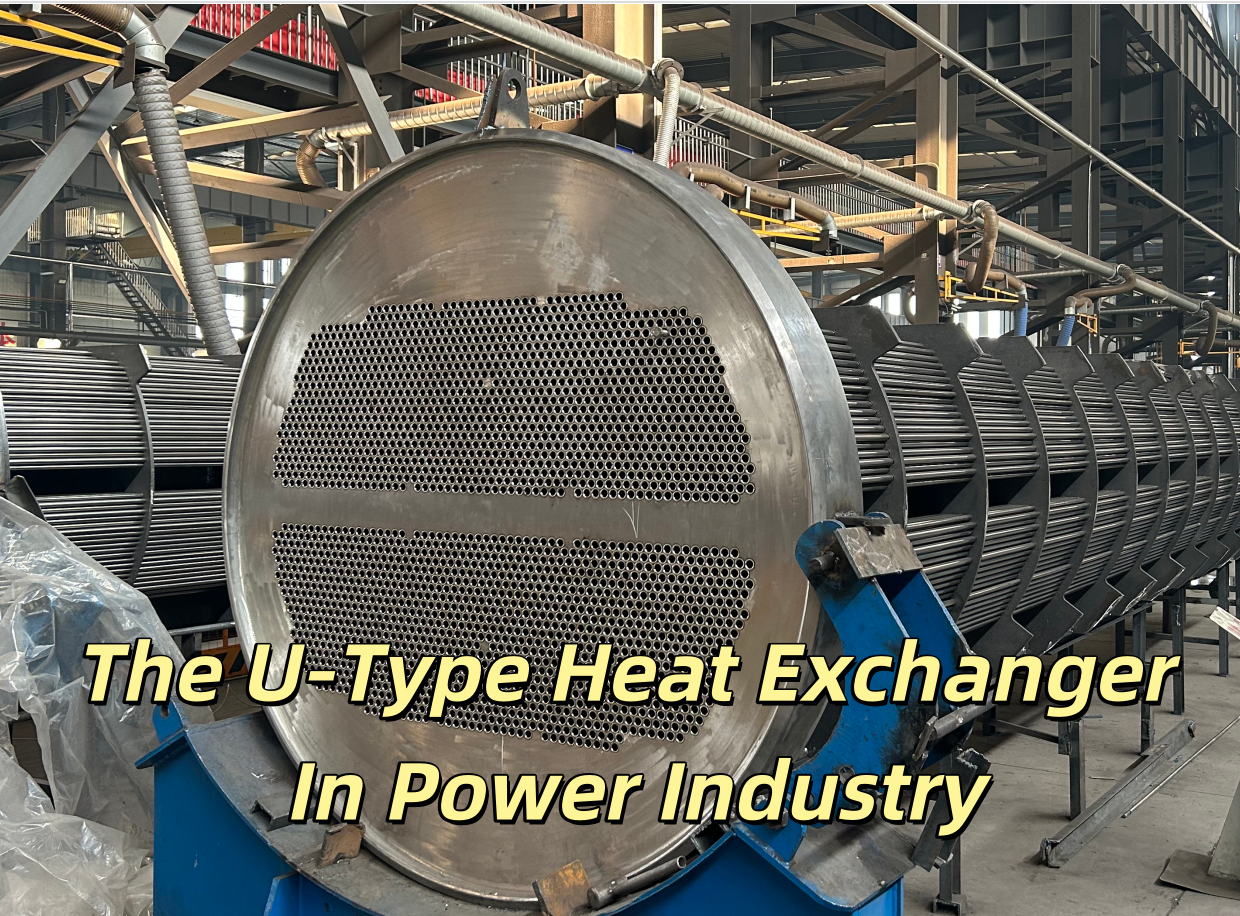

The ASP system condenser of the Hualong One nuclear island

Fixed tube sheet structure, C-shaped tube arrangement

Date: April 27, 2025

Recently, the nuclear island heat exchanger manufactured by Shandong Beichen successfully completed all production processes and set off for a certain nuclear power plant in Hualong One. This equipment has a complex structure and extremely high manufacturing precision requirements. During the production process, it poses strict challenges to welding accuracy and deformation control.

Facing multiple irregular structures, long welds and the risk of thermal deformation, the production team of Beichen adheres to high-standard operations, continuously optimizes process parameters, and ensures that the deformation during the welding process is effectively controllable. The final delivered equipment met the design requirements in terms of appearance quality, structural accuracy and size control, creating favorable conditions for one-time positioning during subsequent on-site installation.

🔧 Device details 🔧

The nuclear island heat exchanger supplied this time is the condenser of the ASP system, installed in the ASP (containment spray) system of the nuclear power plant. It is mainly used to discharge the residual heat of the reactor core under the DEC operating condition where ASG/VDA heat conduction is not available.

Name: ASP System Condenser

Equipment type: Fixed tube sheet structure, C-shaped tube arrangement;

Quantity: 3 units

Application system: ASP system of Nuclear power Plant

Main function: In the event of an accident, it receives steam from the secondary side of the steam generator, condenses it into water, and transfers the heat to the ASP water tank to achieve the discharge of residual heat from the reactor core.

Structural features: The condenser is immersed in an ASP water tank, with the exterior remaining submerged all year round and the inner tube sides filled with demineralized water. The main body has no traditional shell. Special fixtures are used to complete the helium leak detection of the heat exchange tubes and tube sheets.

Manufacturing features: All made of austenitic stainless steel materials; The welding quality is controlled through the anti-deformation process, and the overall size complies with the nuclear power standard. The heat exchange tubes and tube sheets adopt a special hydraulic expansion joint process. The inner surface is smooth, the transition is smooth, and the pull-off force meets the requirements of the RCCM specification.

Working medium: Steam from the secondary side of the steam generator and desalinated water (under accident conditions).

Shandong Beichen will continue to adhere to the principle of "safety first, quality first", efficiently advance the key supporting tasks of nuclear power equipment, and empower the high-quality development of the national nuclear power industry with technologically leading and reliable products.