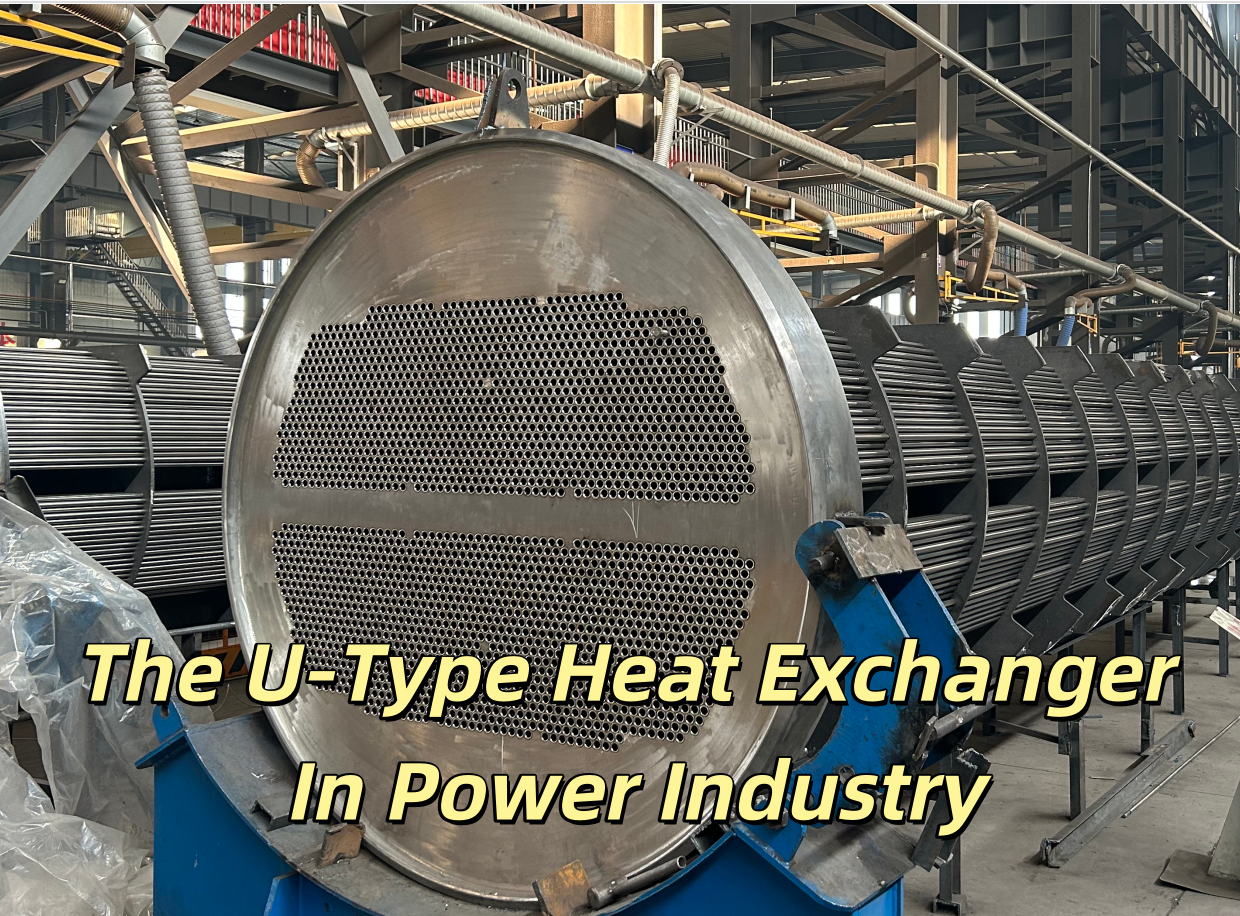

Low-Pressure Heater of Zhejiang Energy Taizhou No.2 Power Plant

Release time:

2025-04-03

[Delivery site]

Zheneng Taizhou No.2 Power Plant Phase II Expansion Project

2×1,000,000 kW Ultra-Supercritical Double Reheat Coal-Fired Unit Low-Pressure Heater

Date: March 28, 2025 Destination: Taizhou, Zhejiang

The company successfully delivered the low-pressure heaters for the Zheneng Taizhou No.2 Power Plant Phase II Expansion Project to the project site. This project constructs 2×1,000,000 kW ultra-supercritical double reheat coal-fired units, which is of great significance for enhancing the power supply capacity in the Zhejiang region and optimizing the energy structure. A total of 12 low-pressure heaters were supplied for this project, with the maximum length of a single unit reaching 17.4 meters. The design, manufacturing, and quality control were strictly carried out in accordance with high standards to ensure the reliable operation of all equipment.

🔧 Equipment Details 🔧

The low-pressure heaters supplied in this batch are shell-and-tube surface heaters with a horizontal U-tube structure. This equipment mainly uses the extraction steam from the low-pressure cylinder of the steam turbine to heat the boiler makeup water, in order to improve the cycle efficiency of the regenerative system, reduce the energy consumption of the boiler, and thereby enhance the overall economy and operational stability of the unit.

Name: Low-Pressure Heater

Equipment Type: Shell-and-Tube Heat Exchanger, Horizontal, U-Tube Structure

Quantity: 12 units

Total Heat Exchange Area: 18,500㎡

Size: The maximum length of a single unit is 17.4 meters

Working Medium: Steam turbine extraction steam and boiler makeup water.

Ultra-supercritical units have put forward higher requirements for equipment performance, material durability, and heat exchange efficiency. As a key component, the low-pressure heater needs to ensure long-term stable operation. Shandong Beichen has always adhered to the development concept of "Safety First, Quality First". From design optimization to precision manufacturing, and then to strict testing, it checks at every level to ensure that the equipment meets the strict standards of ultra-supercritical power stations.