Rotary film deaerator

The rotary film deaerator is a new type of thermal deaerator. The rotary film deaerator is mainly composed of two parts: the deaerator tower head and the deaerator water tank, as well as pipes and external parts.The main component, the deaerator (deaerator tower head), is composed of the outer shell, the new type of rotary film device (film tube), the water grate, the liquid vapor network of the heat storage filler, etc.

- Commodity name: Rotary film deaerator

Classification:

Key words:

Product Details

- 産(chǎn)品描述

-

1.Overview

The rotary film deaerator is a new type of thermal deaerator. The rotary film deaerator is mainly composed of two parts: the deaerator tower head and the deaerator water tank, as well as pipes and external parts.

The main component, the deaerator (deaerator tower head), is composed of the outer shell, the new type of rotary film device (film tube), the water grate, the liquid vapor network of the heat storage filler, etc.

2.Advantages

The rotary film deaerator has the following advantages:

2.1. High deoxidation efficiency, and the qualified rate of oxygen content in feed water is 100%. The oxygen content of the atmospheric deaerator feed water should be less than 15цɡ/L, and the oxygen content of the pressure deaerator feed water should be less than 7цɡ/L.

2.2.Stable operation without vibration. It can be applied to negative pressure start-up and sliding pressure operation, which reduces the manual and complicated adjustment operations during start-up and operation.

2.3.In addition to the advantages of good adaptability, no harsh requirements on water quality and water temperature, it can also operate at about 50% of capacity for a short period of time.

2.4.Small exhaust volume, low energy consumption

3.Structural principle

3.1. Shell: It is made of cylinder body and stamped elliptical head welded together. The medium and small low-pressure deaerators are equipped with a pair of flanges to connect the upper and lower parts for assembly and maintenance. The high-pressure deaerator is equipped with a manhole for maintenance.

3.2. Rotary film group: It consists of a water chamber, a steam chamber, a rotary film tube, a condensate pipe, a make-up water pipe and a primary steam inlet pipe. Condensate and chemical make-up water are sprayed out in a spiral shape at a certain angle through the rotary film device to form a water film skirt, and heat exchange is carried out with the heating steam introduced by the primary heating steam pipe to form a primary deoxidation. The feed water is heated to a saturation temperature close to the working pressure of the deaerator, that is, 2-3°C lower than the saturation temperature, and rough deoxidation is carried out. Generally, about 90-95% of the oxygen content in the feed water can be removed through this rotary film section.

3.3. Sprinkling grate: It is composed of several layers of staggered angles. The feed water is made of steel. The feed water that has been roughly deoxygenated by the rotary film section is distributed for the second time here and falls evenly on the liquid-vapor net installed below it in the form of rain.

3.4. Liquid-vapor net of heat storage filler: It is composed of flat steel strips and a cylinder that are spaced apart from each other, and a stainless steel wire mesh with a certain height is installed inside. The feed water is fully in contact with the secondary steam here, heated to the saturation temperature and deeply deoxygenated. The low-pressure atmospheric deaerator is less than 10ug/L, and the high-pressure deaerator is less than 5ug/L (the ministerial standards are 15ug/L and 7ug/L respectively).

3.5. The deoxygenated feed water in the water tank is collected in the lower container of the deaerator, i.e. the water tank. The deoxygenated water tank is equipped with the latest scientifically designed strong heat exchange reboiling device. The device has the advantages of strong heat exchange, rapid increase in water temperature, deeper deoxygenation, reduced water tank vibration, reduced noise, etc., which increases the service life of the equipment and ensures the safety and reliability of equipment operation.

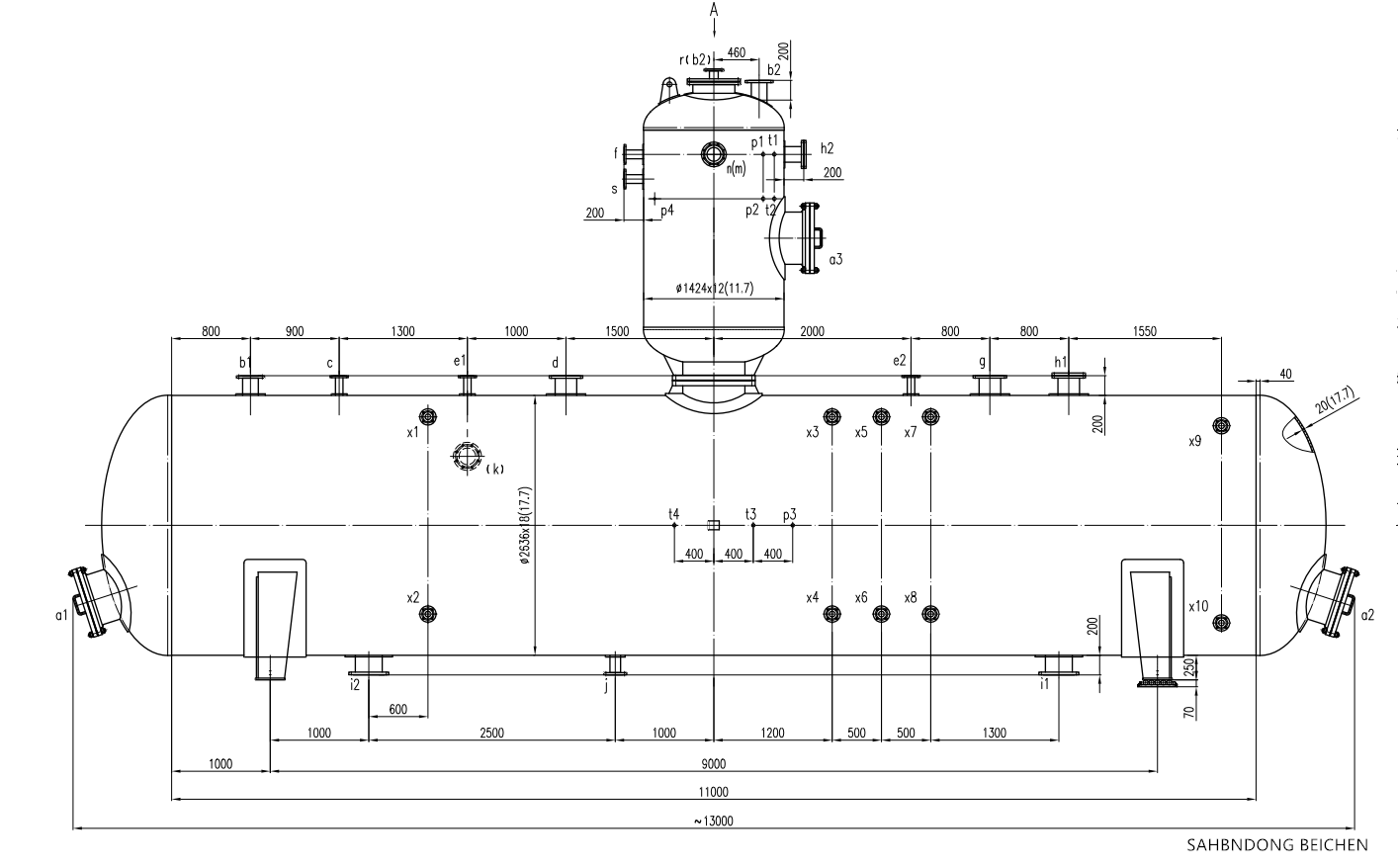

4.Schematic diagram

Get Quote

Note: Please leave your E-mail and our professionals will contact you as soon as possible!

Related Products