Tower

A tower is a device used to carry out physical processes such as separation or absorption, and to change the composition of a complex mixture of gas or liquid. It is also called "tower equipment". The height is relatively large compared to the diameter, and certain accessories are set inside and outside the tower. The internal parts are used to make the gas and liquid, gas and solid, liquid and liquid, or liquid and solid in the material in close contact, and the surface is constantly renewed to complete the process of mass transfer (generally accompanied by heat transfer).

- Commodity name: Tower

Classification:

Key words:

Product Details

- 産(chǎn)品描述

-

1.Overview

A tower is a process equipment with a cylindrical welded structure, consisting of a cylinder, a head (or a cover) and a support. It is a non-standard equipment designed and manufactured specifically for a certain production process requirement. A tower is an upright equipment used for chemical unit operations such as distillation, purification, absorption, and rectification, and is widely used for mass transfer and heat transfer between gas-liquid and liquid-liquid phases. According to the structure of the tower internals, the tower can be divided into a plate tower and a packed tower. If the container only holds materials but does not carry out chemical reactions and other physical and chemical processes, there are no facilities or only simple auxiliary structures, which is also called a tank. Containers are divided into two types according to their type: vertical (axis vertical) and horizontal (axis horizontal). Most towers are pressure vessels.

2.Classification

According to the structure, they are divided into two categories: plate tower and packed tower.

2.1.Plate tower:

A certain number of plates are set inside, and the gas contacts the liquid layer on the plate in the form of bubbling or jetting for material transfer. According to the gas-liquid operation state, it can be divided into bubbling plates, such as float valves, bubble caps, sieve plates and jet plates, such as mesh and tongue-shaped plates. It can also be divided into overflow plates (bubble caps, etc.) and flow-through plates (flow-through grid plates and flow-through sieve plates, etc.) according to whether there is a downcomer.

2.2.Packed tower:

A certain height of packing is installed inside, and the liquid flows from top to bottom along the packing, and the gas contacts the liquid film countercurrently from bottom to top for material transfer. It is often used in operations such as distillation, water absorption, and extraction. According to the structural characteristics, it is divided into random packing (step ring, ball ring and other granular packing) and regular packing (mesh corrugated packing and corrugated plate packing)

3.Application field

There are many types of tower equipment. Tower equipment is one of the most important equipment in chemical, petrochemical and oil refining production. It can make the gas-liquid or liquid-liquid two phases in close contact to achieve the purpose of interphase mass transfer and heat transfer.

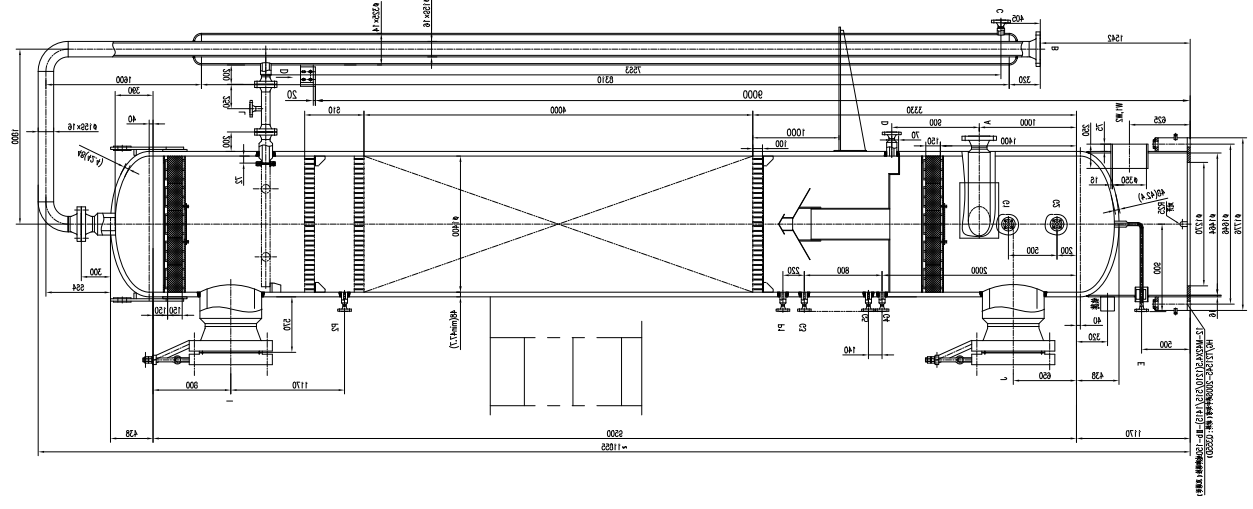

4.Schematic diagram

Get Quote

Note: Please leave your E-mail and our professionals will contact you as soon as possible!

Related Products