Headless Deaerator

Thermal deoxidation of boiler feed water in generator sets, petroleum, chemical and other fields.Headless deaerator is also called built-in deaerator. It has no deaerator tower and the deaeration process is completed in the deaerator water tank. This type of deaerator is an integrated deaerator. Headless deaerator is mainly composed of head, cylinder, support and internal components.

- Commodity name: Headless Deaerator

Classification:

Key words:

Product Details

- 産(chǎn)品描述

-

1.Overview

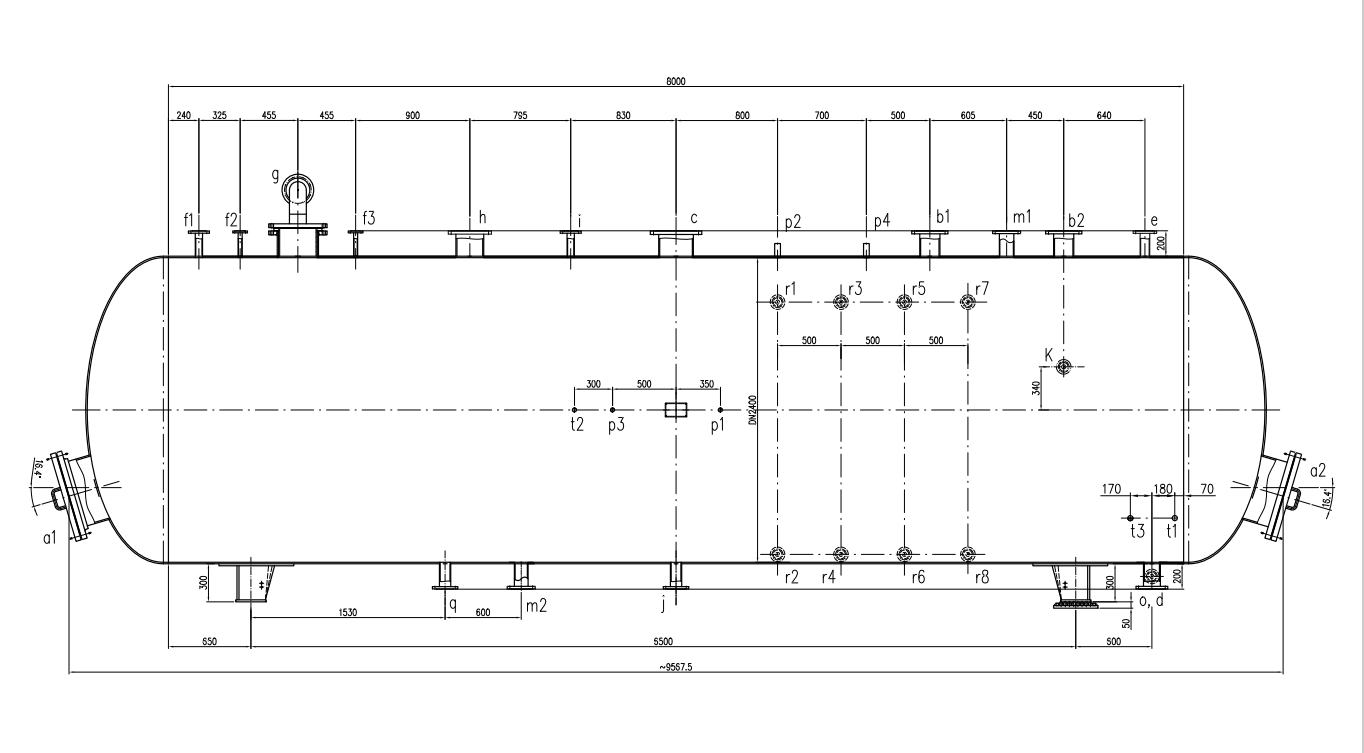

Headless deaerator is mainly composed of head, cylinder, support and internal components. There is a DN600 manhole door on the top of the cylinder for maintenance. There are also two supports on the cylinder, one fixed support and one movable support, with a spacing of 10m. In addition, the water tank is also equipped with an external "T" reinforcement ring to increase the rigidity of the cylinder. In order to prevent excessive pressure inside the deaerator, two DN200 safety valves are also installed on the cylinder. In addition, there are balance containers and overflow devices for measuring water level.

The steam inlet device is divided into auxiliary steam pipe and main steam pipe. Auxiliary steam is used for startup conditions. At this time, the auxiliary steam valve is opened and the main steam valve is closed. The main steam is used for normal working conditions. At this time, the auxiliary steam valve is closed and the main steam valve is opened. In order to prevent water from flowing back into the steam supply pipe, check valves are installed on the main and auxiliary steam supply pipes.

2.Working principle

There are three types of baffles inside the water tank. The nozzle baffle is installed behind the nozzle to enhance the deoxygenation effect. The two flow baffles are installed in the middle of the water tank and in front of the water outlet pipe to control the water outlet flow.

3.Features

3.1.The price is lower than that of conventional headed deaerators (units of 300MW and above);

3.2.Save civil construction costs, and the height of the deaerator room is reduced by 3 to 4 meters;

3.3.The exhaust steam loss is low, and each unit can save hundreds of thousands of yuan in operating costs each year;

3.4.Single container structure, simple system design, avoid stress cracks, excellent seismic performance, light weight, and small vibration;

3.5.One or two disc constant speed nozzles are used, there are no rotating parts, maintenance-free, and highly reliable performance;

3.6.The deaerator medium can be superheated steam, saturated steam, wet steam (90%), or steam/water mixture (1% steam) and hot water.

3.7. good deoxidation effect, strong variable load capacity, wide application range, small exhaust loss, low steam consumption, low operating noise, and comprehensive cost saving.

Installation type: horizontal, vertical.

4.Application:Thermal deoxidation of boiler feed water in generator sets, petroleum, chemical and other fields.

Related link:

5.Schematic diagram

Get Quote

Note: Please leave your E-mail and our professionals will contact you as soon as possible!

Related Products